Filed under: probably bad advice

Seriously, I have no idea what I’m doing… 😬

My wife got pulled into a love affair with archery when she was a Girl Scout, and I’ve always had an interest in it. Now I’m no hunter, and neither is she, but we both like the challenge of it. Given that background, you’d think we’d be pretty heavy into it, right?

Not exactly.

We decided to make an impulse buy, and pick up a pair of compound bows at Gander Mountain in North Canton, OH. We brought them home and ogled over them for a few minutes, before promptly putting them in the closet for a day with better weather. That was when Gander Mountain were having their going out of business sale, if that gives you any idea how dusty these things got in the closet… I mean they were on sale, right?

Fast forward to the modern era, yesterday to be exact, when we took our Girl Scout troop to the archery range at Silvercreek, for a lesson with one of the Girl Scout certified archery instructors. That kinda re-kindled the desire to dust these things off, and figure out what to do next.

So this morning I went on an archeological adventure, a quest into the bedroom closet to find everything we bought, um, <cough> 3 years ago? 😑 Also, to remember where we put our arm span measurements we made when we were younger, slightly more ambitious people.

After uttering a few less than dignified words, I had everything I needed to head down to the shop. First was to set my bow. According to the formula I found my span, 75.5" ÷ 2.5, have me a draw length of 30.2". Max on this bow is 30", so I figure that’s close enough.

Problem here was that one of the screws on the draw length cam was blocked by the limb (don’t give me too much credit, I just googled “parts of a compound bow”), and I don’t have a bow vise, so enter the probably bad advice. I needed the cam to move a little, so I used a 2x4 that was the right size to draw the string just enough for me to get the screw out.

I’m sure that was a dumb idea, I know, you can tell all your friends. It’s OK. But, it worked! Cams reset for a 30" draw, good to go.

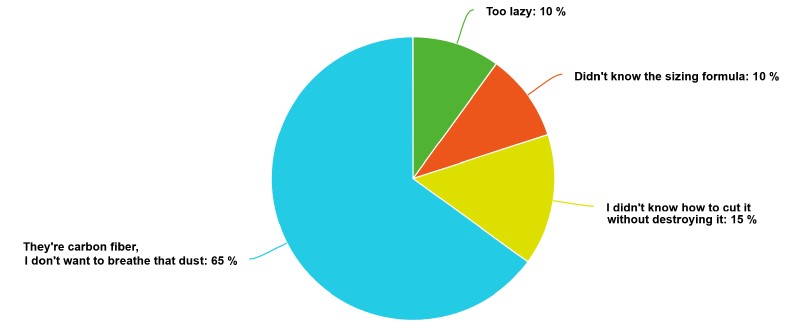

I repeated that bad advice for the wife’s bow, setting her draw length to 26", and proceeded to move on to the arrows. For these, I didn’t bother cutting them down. I’ve provided this handy pie chart to back up the logic behind this decision, I’m sure you’ll all agree that my reasoning is sound.

See? Flawless. That being said, another quick Google revealed that it’s not necessarily critical for the arrows to be sized to my exact draw, so there.

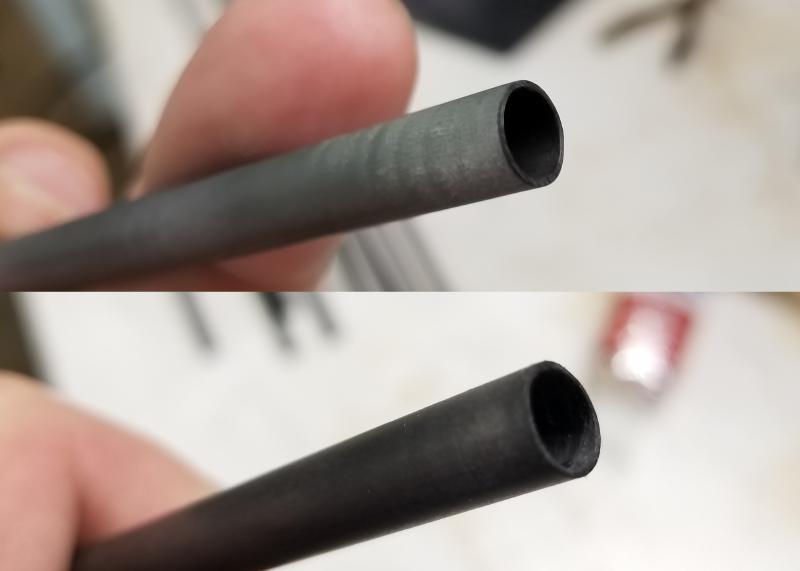

One thing I did that wasn’t recommended, was to throw my main concern about cutting the arrows right out the window, and sand the inside of the arrow shaft just a bit. These arrows are carbon fiber, so you DO NOT want to breathe carbon fiber dust, and you really don’t need much here anyway, so just be gentle. All you’re trying to do is give the epoxy a little more surface area to grab on, a slightly rougher surface to stick to, and I did this with a small scrap of 100 grit sandpaper wrapped around a small drift punch.

Last thing to do here, is to simply glue the inserts into the arrow shaft with some epoxy. I may not know a whole lot about archery, but I do know how to glue things together, plenty of experience here gluing my fingers to balsa airplane parts.

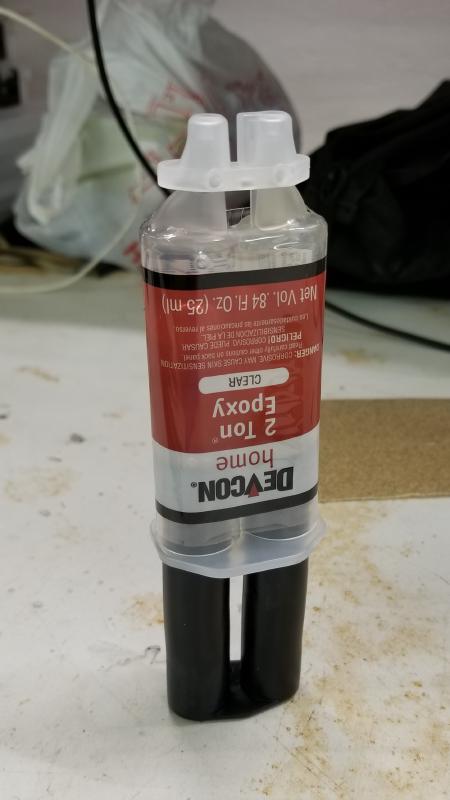

When it comes to this, the slower the epoxy the better. If you try to do a whole batch of arrows using 5 minute epoxy, you’re going to have a bad time, k? If you have the time to go to a hobby supply store, just get their store brand 60 minute epoxy. If you don’t have the time to go, or the inclination to order, you can be like me make due with Devcon 2 Ton epoxy. Because I was too lazy, and too impatient to source the 60 minute from Tower Hobbies. After mixing that up, put a small dab on the bottom of the insert.

Rotate the insert quite a bit as you set it into the shaft of the arrow, working it in a bit, then pulling it out a touch, then in again, working it back and forth as you’re rotating it. This will help to coat the entire mating surface of the insert and the arrow, making sure you get a good grip. When you’re done, just wipe off the excess epoxy with a shop towel. If you want to go the extra mile, wet the shop towel with a little rubbing alcohol, that will help to clean up the film of the excess.

That’s it! Just need to wait for these to cure, then I get to try to not shoot myself in the foot. Fun times.

Pro Tip: If you use the epoxy in the syringe like I did here, store it open end up. Don’t ask, just do. If you don’t, you’ll find out why a few weeks later. 😉